You have no items in your shopping cart.

HOW OUR CUSTOM HEATING PROCESS WORKS

1. RECEIVE A QUOTE WITHIN 24 HOURS

Submit the 30-second custom quote form and we'll get you a quote within 24 hours.

2. QUOTE REVIEW

Once your team accepts the quote we will collect additional project information to begin designs.

3. TAILORED ENGINEERING

We create custom designs to meet your specific needs.

4. SCHEDULE, BUILD, SHIP

We create your heaters and ship them, within 2 weeks for most projects.

Benefits

- Customized solutions for unique needs and requirements.

- Efficient and effective problem-solving for various industries.

- Say goodbye to lost revenue and costly downtime caused by cold weather interruptions.

- Boost productivity and profit with reduced energy waste and streamlined operations.

- Our reps will reach out within 24 hours.

Common custom solution

FREEZE PROTECTION

PROCESS HEATING

TEMPERATURE CONTROLS

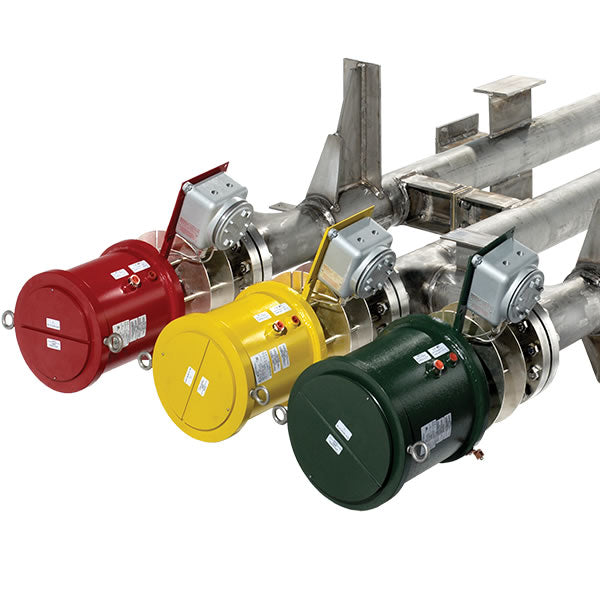

- Tank Heaters

- Pipe Heaters

- Heat Trace Systems

- Valve/Actuator Heaters

- Pump/Equipment Heaters

- Instrumentation/Transmitter Heaters

- Heating Chutes/Hoppers

- Heating Gas Delivery Systems

- Concrete Curing/Ground Thawing

- Snow Melting Mats

- Material Handling/Staging

- Safety Equipment

- Tank Heaters

- Immersion Heaters

- Pipe Heaters

- Gas Delivery Systems

- Curing Materials

- Portable Ovens/Bulk Material Heaters

- Personnel/Space Heating

- Material Handling/Staging

- OEM Heaters

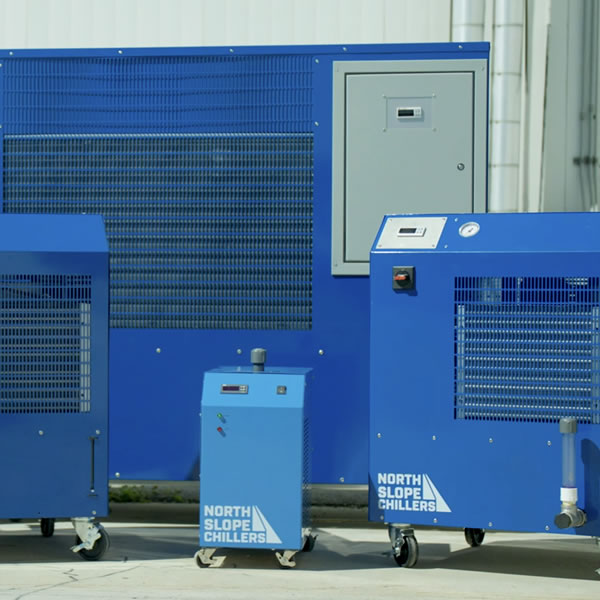

- Industrial Chillers

- Industrial Cooling Jackets

- Air Handlers

- Freeze Protection Controllers/Sensors

- Process Heating Controllers/Sensors

- Temperature Controllers

Common custom solution

FREEZE PROTECTION

- Tank Heaters

- Pipe Heaters

- Heat Trace Systems

- Valve/Actuator Heaters

- Pump/Equipment Heaters

- Instrumentation/Transmitter Heaters

- Heating Chutes/Hoppers

- Heating Gas Delivery Systems

- Concrete Curing/Ground Thawing

- Snow Melting Mats

- Material Handling/Staging

- Safety Equipment

PROCESS HEATING

- Tank Heaters

- Immersion Heaters

- Pipe Heaters

- Gas Delivery Systems

- Curing Materials

- Portable Ovens/Bulk Material Heaters

- Personnel/Space Heating

- Material Handling/Staging

- OEM Heaters

- Industrial Chillers

- Industrial Cooling Jackets

- Air Handlers

TEMPERATURE CONTROLS

- Freeze Protection Controllers/Sensors

- Process Heating Controllers/Sensors

- Temperature Controllers

WE LOVE CREATING

CUSTOM HEATING SOLUTIONS

FOR OUR CUSTOMERS

URS CORPORATION:

COLD WEATHER

FRAC TANK SOLUTION

Heat Authority supplied the frac tank heatingsystem currently working on site. Theheating system installed quickly despite rainy weather, and has protected the contents from freezing

EDWARD SKUCHAS, ENGINEER WITH URS

URS Corporation implemented a new solution to keep ground water collected in frac tanks from freezing at the Knolls Atomic Power Laboratory. Located in Niskayuna, NY, the Knolls Atomic Power Laboratory (KAPL) is dedicated to the support of the US Naval Nuclear Propulsion Program. KAPL was developed after World War II in 1946 under a contract between General Electric and the United States government. Today, KAPL is a government-owned, contractor-operated laboratory run by Bechtel Marine Propulsion Corporation for the US Department of Energy. KAPL is responsible for the research, design, construction, operation, and maintenance of U.S. nuclear- powered warships, and manages work on nuclear ships at numerous shipyards across the country.

On January 7, 2008, the U.S. Department of Energy (DOE) awarded URS Corporation a $67 million task order to deactivate and demolish the Separations Process Research Unit (SPRU) located at the Knolls Atomic Power Laboratory in Niskayuna, New York. The site, used for U.S. atomic weapon reserach, closed in 1953. Part of the operation involves collecting, transferring, and storage of ground water in frac tanks located on-site. URS Corporation realized they needed to keep the ground water in the frac tanks from freezing. They contacted Heat Authority® for a custom solution. Heat Authority's world-class custom design team accepted the challenge and delivered quickly to have the system in place in time for winter. This solution provided freeze protection, allowing for continuous operation and minimized downtime during the project. URS completed their project on time and on budget thanks to Heat Authority's custom frac tank heaters.