Ruffneck Explosion-Proof Heaters

Ruffneck™, a key brand of Thermon Heating Systems, Inc., has a broad product line

including heat-exchanger unit heaters, explosion-proof electric air heaters, industrial

electric air heaters and explosion-proof thermostats.

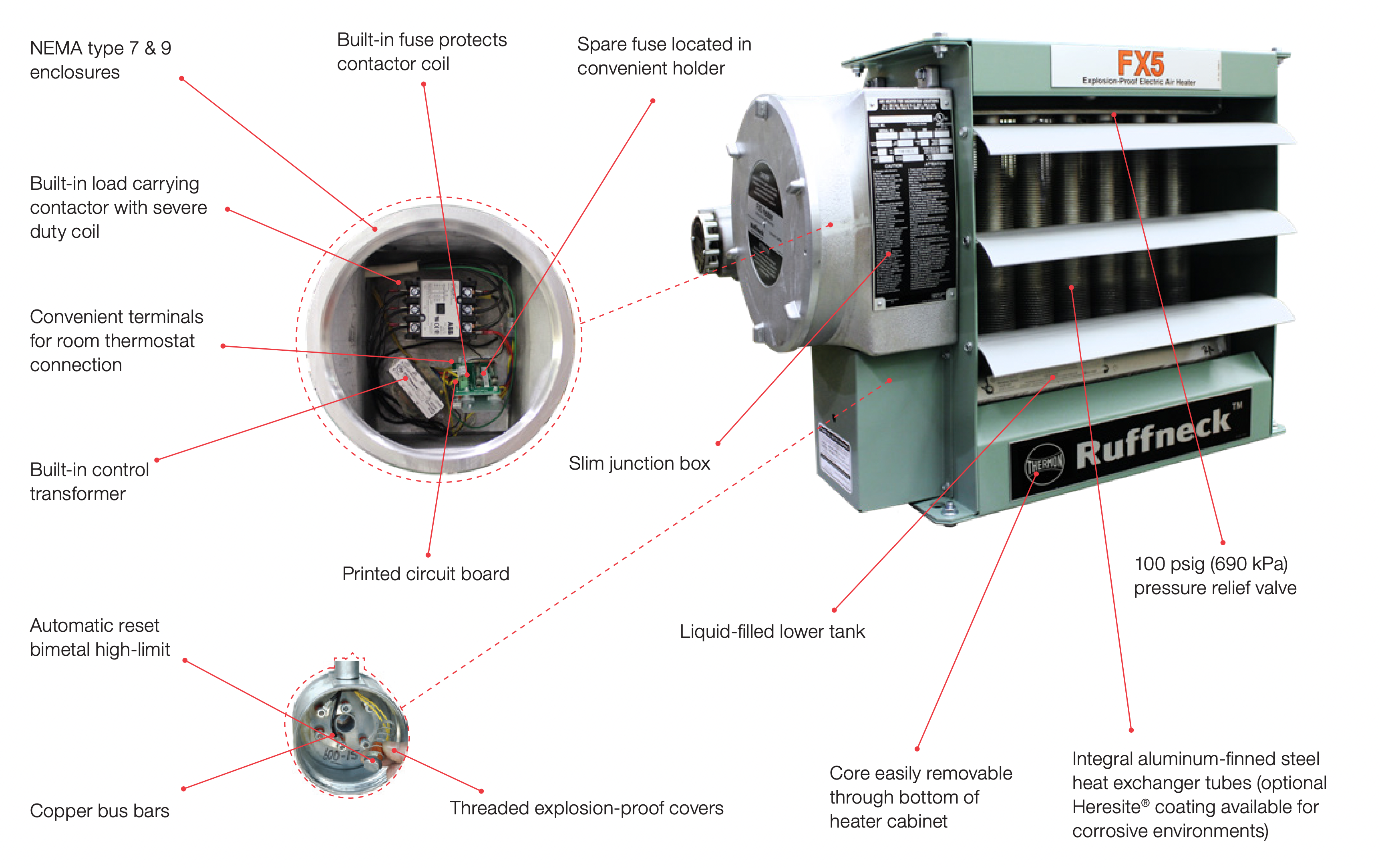

FX Series

The Ruffneck™ FX Explosion-Proof Electric Air Unit Heater is designed for the harshest industrial environments and intended for dry indoor industrial applications such as oil refineries, petrochemical plants, pulp and paper mills, grain elevators, hazardous waste storage facilities, wastewater treatment plants. This heater is ideal anywhere that specific explosive gases or dust may be present.

The FX5 offers a larger junction box for easier installation, additional limit controls, and a heavy-duty core.

The heater core assembly is contained in a sturdy, epoxy-coated 12-gauge steel cabinet, which also carries the motor and fan assembly. Adjustable louvers allow directional control of the airflow. A narrow gap, two-piece fan guard is provided to shield all moving parts. All fasteners are zinc plated for corrosion protection.

Ruffneck™ heaters are built to last. All Ruffneck™ products are subjected to exhaustive technical analysis and testing during design and development and are manufactured under a registered quality assurance program. As a result, they have consistently proven their safety and reliability. For hazardous location heating, rely on the Ruffneck™ FX5 heater for the most dependable, trouble-free service available. Suitable for the following hazardous location classifications:

- Class I, Division 1 & 2, Groups C & D

- Class II, Division 1, Groups E, F & G

- Class II, Division 2, Groups F & G

- Class I, Zones 1 & 2, Groups IIA & IIB

- Temperature Code T3B 329°F (165°C)

EFX Series

The EFX Explosion-Proof Exhaust Fan is designed for hazardous and general-purpose industrial applications. The EFX is constructed with epoxy-coated steel panels and spark-resistant aluminum fan blades for the ventilation of combustible materials, vapors, and hazardous fumes. The EFX is fully assembled for easy installation and has explosion-proof motors that are CSA approved and/or UL-listed, with fan guards conforming to OSHA specifications.

FR Series

Ruffneck™ FR Heat Exchanger Unit Heaters are extra heavy duty (including heavy gauge steel construction) to meet the most demanding service and long life requirements for rugged industrial applications. The FR Series heaters are specifically designed for steam applications that may be subject to freezing conditions and are of particular value for outdoor applications. Explosion-proof models suitable for hazardous locations are available on custom orders.

Engineered for ease of maintenance, all parts are easily removed. All fasteners are plated capscrews; no sheet metal screws are used. Heat exchanger cores are of steel construction with tension wounds and close-fitting aluminum fins. They are resistant to corrosive agents (including hydrogen sulfide).

All units are equipped with a narrow-gap, epoxy-coated fan guard. Choose from several optional UL listed and/or CSA-approved motors with various voltages, phases, and frequencies. All FR models have Canadian CRN approvals and are CSA certified for hazardous locations:

- Class I, Division 1 & 2, Groups C & D

- Class II, Division 1 & 2, Groups E, F, & G

- Class III, Division 1 & 2; Temperature Code T3B 329˚F (165˚C)— on applicable models only.

CR1 Triton

Ruffneck™ CR1 Triton™ Series is a new generation of NEMA 4X corrosion-resistant washdown heaters. The first UL-listed Type 4X heater with models ranging from 3 kW to 39 kW.

IMPORTANT: Ruffneck™ CR1 heaters are suitable for non-hazardous locations only. For washdown applications, use water pressure of less than 70 psi.

Features

- The entire heater is NEMA Type 4X

- Epoxy-coated fan blade

- 16-gauge stainless-steel cabinet

- Custom-configured stainless-steel elements

- Optional built-in accessories

- Stainless-steel wall/ceiling mounting kit

- 120 V controls

- Stainless-steel temperature high-limit

Benefits

- Increased safety and protection against water penetration

- Added corrosion protection

- Better resistance to corrosion for longer life

- Improved heat distribution and corrosion protection

- Flexibility and reduced field installation costs

- Flexible options for mounting heater

- Better contactor pull-in reliability

- Increased safety and reliability

CX1 ProVectorVector ® Series Explosion-Proo

For hazardous locations heating, rely on the Ruffneck™ CX1 ProVector® for the most dependable, trouble-free service available. Thermon Heating Systems, Inc. manufactures explosion-proof air heaters to satisfy the demanding requirements of the oil and gas well drilling industry. The harsh operating conditions of this application require the utmost in heater reliability.

The unique design features and rugged, quality construction details that have made Ruffneck™ heaters the choice of the oil and gas industry are also appreciated by other heavy-duty industries worldwide.

Features

- Available in 1-phase or 3-phase

- Available up to an industry-leading 10 kW

- Sloped-top cabinet

- No exposed copper or brass

- High-velocity airflow

- 14-gauge steel cabinet, available with stainless-steel construction

- One of the shortest cabinet lengths available

- Optional built-in thermostat

- Incoloy® 840 heating elements

- Radial-embossed aluminum plate fins

- Galvanized steel mounting brackets

- Approvals -Groups A, B, C, D; IIA, IIB & IIC; available IP55 moisture ingress protection

Benefits

- Prevents objects from being set on top, which restrict airflow

- Corrosion resistant, suitable for H2S environments

- Heats up area faster with better heat distribution

- Rugged reliability and unsurpassed corrosion resistance available with stainless-steel construction

- Smaller profile utilizes less wall and floor space

- Reduced field installation costs

- Longer life expectancy

- Reduced fin warping for better heat transfer capabilities

- Quick installation

- Industry-first approvals for built-in thermostats with Groups A, B, C, D; IIA, IIB, and IIC ratings

HP Series

Ruffneck™ HP Heat Exchanger Unit Heaters are extra heavy duty (including heavy gauge steel construction) to meet the most demanding service and long life requirements for rugged industrial applications, such as space heating and liquid cooling. The HP Series heaters are suitable for a wide range of heating fluids, including steam, hot water, glycol, oil, etc. Explosion-proof models suitable for hazardous locations are available on custom orders.

Engineered for ease of maintenance, all parts are easily removed. All fasteners are plated capscrews; no sheet metal screws are used. Heat exchanger cores are of steel construction with tension wounds and close-fitting aluminum fins. They are resistant to corrosive agents (including hydrogen sulfide).

All units are equipped with a narrow-gap, epoxy-coated fan guard. Choose from several optional UL listed and/or CSA-approved motors with various voltages, phases, and frequencies. All HP models have Canadian CRN approvals and are CSA certified for hazardous locations:

- Class I, Division 1 & 2, Groups c & d

- Class II, Division 1 & 2, Groups E, F, & G

- Class III, Division 1 & 2; Temperature Code T3B 329˚F (165˚C) -(on applicable models only).

To view more specifications, view the Ruffneck catalog here.