Electric Explosion-Proof Heaters

Norseman™ explosion-proof electric air heaters and thermostats are low-maintenance solutions for many applications. From panel heaters to unit heaters, the Norseman™ line provides innovative forced air or natural convection solutions to your hazardous area heating requirements across a wide kilowatt range.

Core Applications of Norseman™ Explosion-Proof Electric Heaters

Norseman™ explosion-proof heaters are available for almost all hazardous location requirements. Typical applications for Norseman™ explosion-proof heaters include:

- Oil platforms and refineries

- Control cabinets and small enclosures

- Storage rooms for paints and cleaners

- Grain elevators

- Flour mills

- Spray booths

- Gas plants

- Pump houses

- Marine and offshore

- Cleaning and dyeing plants

- Water and sewage treatment plants

- Compressor stations

- Pulp and paper mills

- Cement plants

Norseman™ Heaters are Durable

With anodized, copper-free aluminum housings and heat sinks and nickel-plated, low-watt-density elements, the Norseman™ line of electric explosion-proof heaters is designed to provide years of reliable, low-maintenance service.

Norseman™ Heaters Have Simplified Wiring

To facilitate installation, Norseman™ heaters employ the patented x-Max® housing with screw-on covers and slide-out terminal block trolley.

Norseman™ Heaters Use the Innovative x-Max® Terminal Housing

Thermon Heating Systems’ explosion-proof terminal housing features the unique x-Max® “Track and Trolley” system. Typical uses include a terminal enclosure, a control station, or a junction box, or it can be adapted for use in custom-engineered applications. Five standard diameters, offered in lengths up to 3" (76 mm), can cover most of your explosion-proof housing requirements. No longer is it necessary to remove dozens of bolts to gain access to housing components for installation, adjustment, or servicing. With longer type XH housings, components are mounted to the trolley. To service, simply unscrew the end cover and slide the trolley out of the enclosure.

The “Track and Trolley” wiring system allows the user to mount all electrical components to an aluminum “Trolley,” make all wiring connections outside of the enclosure and simply slide the “Trolley” along the extruded “Track.” Series 1 and 2 housings use extruded aluminum trolleys, and Series 3, 4, and 5 housings use trolleys made from 14-gauge sheet metal.

XB - Explosion-Proof Natural Convection Heaters

The Norseman™ XB Series convection heater, with ratings up to 5000 watts, is designed for heating spaces where explosive substances are or may be present. The Norseman™ XB is available with either CCSAUS or CE ATEX approvals. All units can be fitted with an externally adjustable thermostat.

With the Norseman™ XB, you get a safe and reliable heater with a handsome appearance and state-of-the-art design.

Applications

Typical applications for the Norseman™ XB include:

- Control cabinets and small enclosures

- Storage rooms for paints and cleaners

- Grain elevators

- Flour mills

- Spray booths

- Gas plants

- Pump houses

- Marine and offshore

- Oil platforms

- Cleaning and dyeing plants

XB Sizing

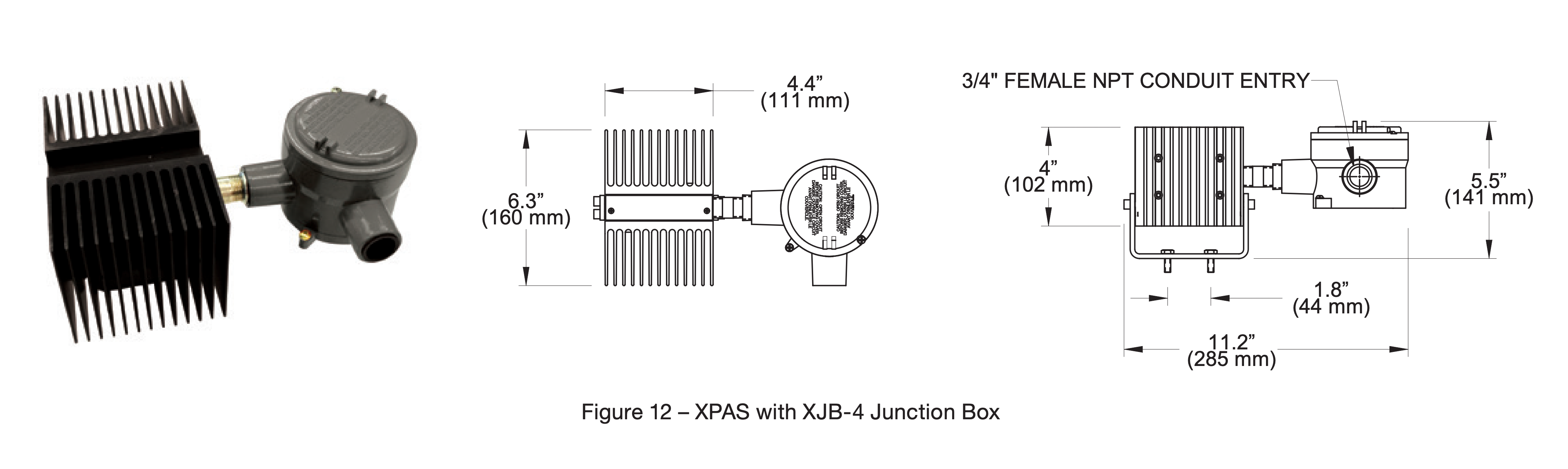

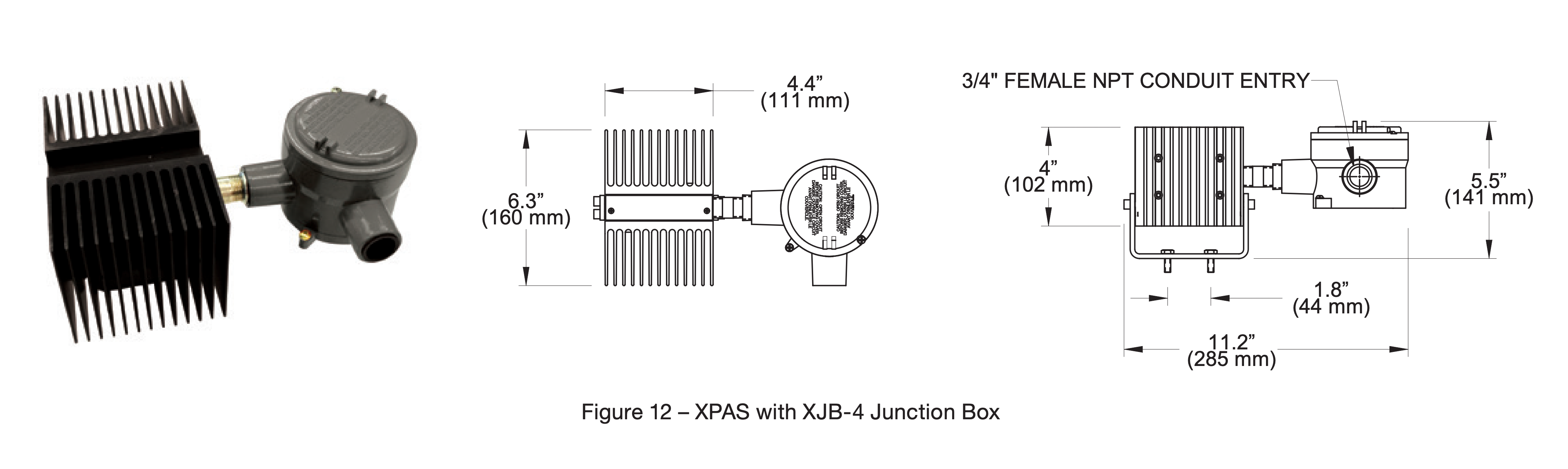

XPA - Explosion-Proof Panel Heaters

The Norseman™ XPA Series explosion-proof panel heater is the latest innovation in the Norseman™ line of hazardous location heating products.

The Norseman™ XPA heater is available in 120V, 208V, 240V, 50 Hz, and 60 Hz configurations. The Norseman™ XPA heater is CCSAUS certified for Class I, Divisions 1 & 2, Groups A, B, C & D, and ATEX/IECEx/EAC certified for Ex d IIC or IIB, T2 (215ºC), T3 or T4, Gb IP66.

Applications

The Norseman™ XPA Explosion-Proof Panel Heater is ideal for freeze protection of control enclosures in locations where explosive atmospheres may exist and other confined or enclosed areas with moderate heating requirements.

Typical applications include:

-Control cabinets

-Instrument enclosures

-Small storage rooms

-Cabinets for volatile products

Construction

The Norseman™ XPA Explosion-Proof Panel Heater’s custom extruded aluminum convector assembly features a high-density fin array to maximize surface area and ensure safe and efficient convective heat transfer. The Norseman™ XPA heater is anodized black for maximum heat transfer and corrosion resistance.

The standard heater is configured with an explosion-proof junction box and includes a mounting bracket and hardware. As a precaution against excessive convector temperatures, the unit comes standard with two levels of safe temperature control. The primary control is a nonadjustable thermostat set to control the space temperature between 50°F and 64°F (10°C and 18°C). The secondary control is a thermal fuse with a nonadjustable limit set to the maximum temperature allowed for the temperature code classification. Optional junction boxes, optional pre-set thermostats, adjustable thermostats, and protection grilles are available.

To view more specifications, view the Norseman catalog here.