You have no items in your shopping cart.

What is Infrared Heating?

Regarding heating large, open spaces, infrared heaters are often the best option. There can be many different industrial applications for heating but let's focus on infrared drying and curing ovens. That's where industrial infrared gas catalytic heaters come in. These heaters are specifically designed to be used for these curing and drying applications where other sources won't be as efficient.

An infrared heater is a beneficial tool as it helps with the quick and even transfer of heat. This can then be applied to different areas, such as providing warmth in a building, aiding in manufacturing processes, stopping items from freezing gradually over time, creating a comfortable working environment for staff members, and more. If you are looking specifically for carbon fiber or epoxy resin curing, check out this article to learn more.

How does infrared heat work?

Infrared heaters work by emitting a wavelength of light that is absorbed by objects in the room. There are medium-wave infrared or short-wave infrared heaters. This process heats the objects directly rather than heating the air around them. This makes infrared heaters much more efficient than other types of heaters, as there is no wasted energy heating up space. As the infrared panels generate heat, that heat is emitted throughout the room. Infrared energy is one of the most efficient types of heat energy and allows for heat transfer to take place without requiring as much input.

Infrared heaters work by emitting a wavelength of light that is absorbed by objects in the room. This process heats up the objects directly rather than heating the air around them. This makes infrared heaters much more efficient than other types of heaters, as there is no wasted energy heating up space. Additionally, because the heat is directed at specific objects, people and animals in the room will not feel overheated or uncomfortable.

What are the Benefits of Using Infrared Heaters

There are many benefits to using infrared heaters, but there are a few key advantages that make them the best choice. First, because they don't rely on heating the air around them, they don't create any sparks or flames that could potentially ignite explosive materials. Second, they can be used in areas with poor ventilation without creating any health hazards. And finally, they're very efficient, so you'll save money on your energy bills while still keeping your employees safe and comfortable.

What are the disadvantages of infrared heating?

A common question that gets asked is, are infrared heaters safe? These coils get very hot, making them dangerous in certain situations. Temperature control is crucial and, with certain units, is limited. Zone heating can be challenging in some situations – especially if the room is moving fast. Stop heating after shutdown.

Specifications of Infrared Heaters

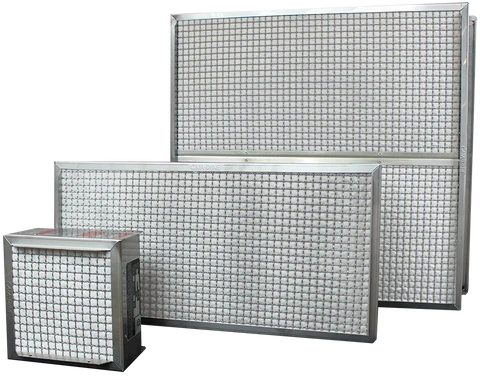

The infrared heating system has so many different specifications that it can be tricky to claim. First and foremost, fuel or energy sources. As we have said previously, infrared heaters use either electricity, natural gas, or propane. Different heating systems have different heating outputs and operating temperature. Some heating systems also contain timers. Other details include the filtering control, wheels weighing, fans, and temperature controls.

The most efficient infrared heating panels for curing and drying purposes are these infrared gas catalytic heaters that allow you to have manual control or electronic control options. These panels also provide you with various heater mounting bracket configurations to make it easy to apply these panels to your specific application.

$888.80 USD

12" x 24" WX Series Infrared Gas Catalytic Heater 10,000 BTU

Industrial uses for Infrared Heaters

A variety of industrial uses require using heatless fire to heat a surface for drying processes. In all application areas, precision and controlled heat are essential to maintain quality products. Modern technological production requires efficient energy and heating technologies that provide sufficient heat levels but at providing low cost. Infrared heaters are engineered and constructed so that the surface is heated rapidly, evenly, and uniformly.

The use of infrared heaters for industrial heating applications is becoming increasingly popular. Infrared heaters provide a rapid, even, and uniform heat that is perfect for drying and heating surfaces. They are also a very efficient form of heat, which makes them an attractive option for companies looking to save on energy costs. Some of the most common industrial uses for infrared heaters include.

Drying processes – Infrared heaters are commonly used in a variety of drying processes, including drying paints, liquids, and other materials. This helps to reduce waste and increase efficiency.

Curing products – Many manufacturing companies use infrared heaters to cure their products quickly and efficiently. This helps to speed up production times and ensure consistent results.

Heating equipment – Infrared heaters are often used in conjunction with industrial heating equipment, such as ovens or furnaces, to provide uniform and high-quality heating. With a variety of electric heating elements, you are able to achieve a more efficient heating process overall.

While there are many different applications for infrared heaters in industrial settings, they are an extremely effective and efficient tool for increasing productivity, reducing costs, and maintaining a high-quality product. Whether you are looking to heat equipment or cure products, infrared heaters are a great option for many different industrial applications.

Is Infrared Heating Good for Your Application

If you're looking for a safe and effective way to heat in various applications, industrial infrared heaters are the perfect solution. These heaters offer many benefits over other types of heaters, including increased safety, improved energy efficiency, and better ventilation. Let an infrared heater, like our Cata-Dyne heaters, solve your heating problems so that temperature control issues can become a thing of the past.